Why Non-Woven Bags?

Non-woven bags are made from non-woven fabrics, which are created by bonding or felting fibers together using heat, chemicals, or pressure. This process results in a strong, durable material that can withstand heavy loads and frequent use. Non-woven bags are also eco-friendly and can be recycled, unlike most plastic bags which take hundreds of years to decompose.

Non-woven bags are also versatile and can be used for various purposes, including shopping, storing, and carrying items. They come in various shapes, sizes, and colors, making them suitable for different occasions and settings. Non-woven bags are also cost-effective, as they can be produced in large quantities at affordable prices.

Non-Woven Bag Making Machines

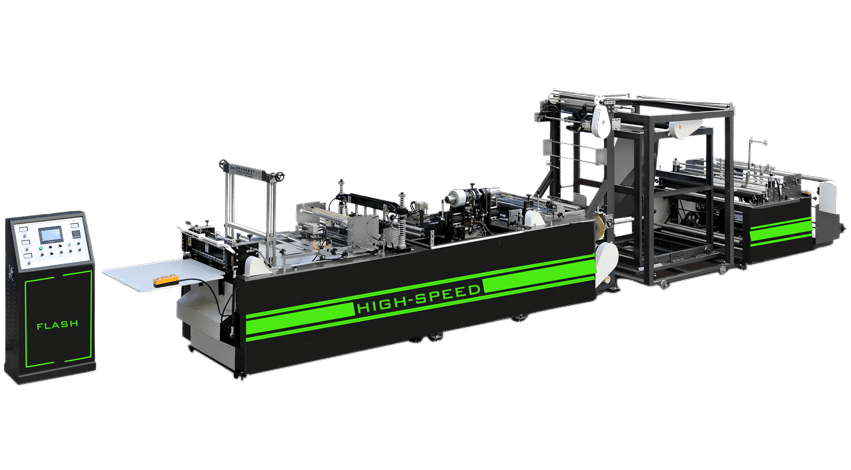

Non-woven bag making machines have made it easier and faster to produce non-woven bags in large quantities. These machines come in different models and designs, depending on the bag size, shape, and the level of automation required. Some of the common types of non-woven bag making machines include manual, semi-automatic, fully automatic, and ultrasonic non-woven bag making machines.

Manual non-woven bag making machines are operated by hand and are suitable for small-scale production. Semi-automatic non-woven bag making machines are partially automated and require minimal human intervention. Fully automatic non-woven bag making machines are fully automated and require no human intervention, except for loading and unloading raw materials. Ultrasonic non-woven bag making machines use high-frequency vibrations to bond the fabric layers together, creating a strong, durable bond.

Benefits of Non-Woven Bag Making Machines

Non-woven bag making machines have several benefits over traditional bag making methods. Firstly, they are faster and more efficient, producing bags in large quantities within a short time. This reduces production costs and enables manufacturers to meet the high demand for non-woven bags.

Secondly, non-woven bag making machines are more accurate and consistent, ensuring that each bag is of the same quality and specifications. This increases customer satisfaction and promotes brand loyalty.

Thirdly, non-woven bag making machines are easy to operate and require minimal training. This makes it possible for small business owners and entrepreneurs to venture into the non-woven bag making industry, creating more job opportunities and promoting economic growth.

Conclusion

Non-woven bag making machines are transforming the bag-making industry, enabling manufacturers to produce eco-friendly, durable, and cost-effective bags in large quantities. These machines are faster, more efficient, accurate, and easy to operate, making it possible for small business owners and entrepreneurs to venture into the industry. Non-woven bags are also versatile, eco-friendly, and cost-effective, making them a popular alternative to traditional plastic bags. With the increasing demand for sustainable and eco-friendly products, non-woven bags and non-woven bag making machines are likely to become even more popular in the future.