Products Details

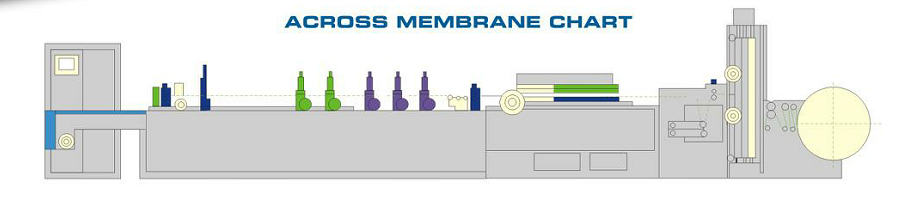

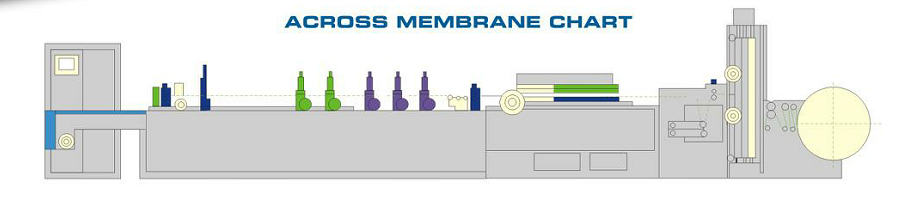

Application: This machine is suitable for making 3 side sealing bag with material plastic-plastic, plastic-paper, paper-paper laminated. Feature: 1. Whole machine PLC control with touch screen which is convenient for operation 2. Unwind constant tension control, EPC device 3. Three servo motor material dragging controlling system 4. Up-down sealing inverter motor control 5. PID for sealing bar temperature adjustment,automatic control, set by man-machine interface. 6. Pneumatic auto punching device, trim cutting and auto rewinding,static eliminator 7. Temperature adjustment: 0-300℃ 8. Quantity and batch is accumulated automatically, preset is available. 9. Operation method is by length fixation control or photocell tracking. 10. Punching can be set as continuous,interval or stop, punching time can be pre-set. 11. Material skip feeding: 1-6 times available 12. Batch conveying function available, the quantity of batch can be pre set.

Specification:

Specification: | Model | ZUA400 | ZUA500 | ZUA600 |

| Max material width | 850mm | 1050mm | 1250mm |

| Max roll diameter | 600mm | 600mm | 600mm |

| Bag making speed | 160 piece/min | 160 piece/min | 160 piece/min |

| Max linear speed | 40m/min | 40m/min | 40m/min |

| Total power | 35KW | 40KW | 45KW |

| Weight | 4000KG | 4500KG | 5000KG |

| Dimension | 9000*1800*1870mm | 9000*1900*1870mm | 9000*2700*1870mm |

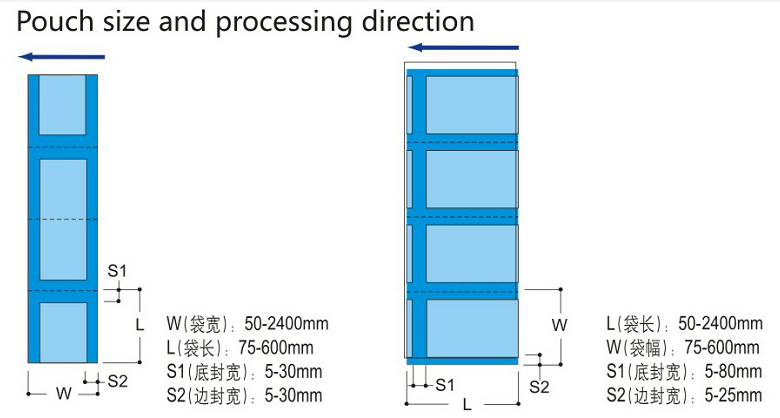

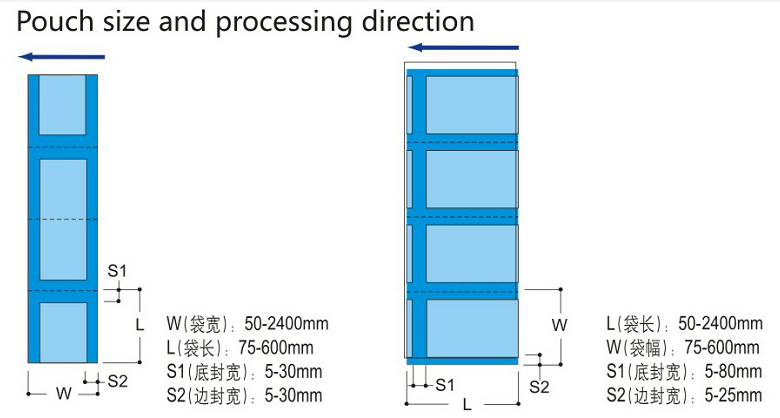

Bag Sample:

China Plastic Bag Cutting Machine,

China Plastic Bag Maker and Bag Making Plant,

Printing Machine Flexo,

Pe Film Blown Machine,

High-speed Label Printing Machine,

Printed Napkin Machine,

Ultrasonic Mask Making Machine,

Flexo Print Machinery,

Slitting Machine,

Pet waste disposal machine,

Specification:

Specification: